The Ozene treatment process transforms aluminium by incorporating quaternary ammoniums (the active agents used in anti-bacterial gels and wipes) into a surface so hard it can only be scratched by diamonds!

For every cm2 of surface on every layer of microns there are over 1 billion quaternary ammonium molecules. Each and every molecule can kill multiple microbes with no effect on the efficacy.

This ensures that the surface is offering full protection all the time, and never loses its effectiveness.

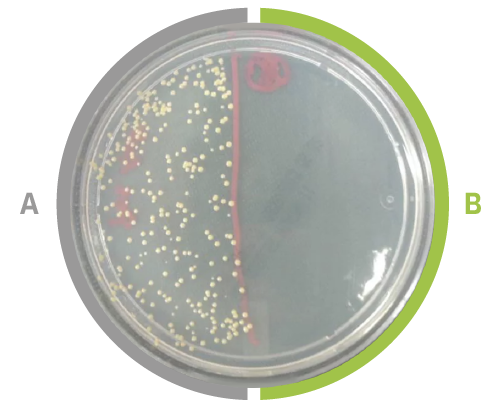

This image from under a microscope shows untreated aluminium on the left and Ozene treated aluminium on the right after being exposed to bacterial cultures.

The four steps to treating aluminium with Ozene:

Step 1: Preparation

Before proceeding with the anodising, the surface must be cleaned in order to get rid of any oils and greases. Then, it is deoxidised in order to remove the natural oxidation on the aluminium. Finally, the aluminium is stripped by soaking it in order to get a uniform surface to start treatment.

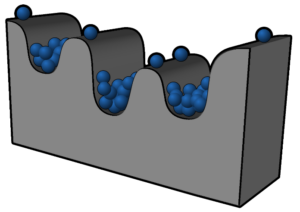

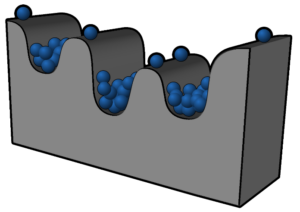

Step 2: Anodising

This step is carried out by passing a current through an electrolyte. This creates microscopic pores for the antimicrobial substance to reside in. This step has to be managed carefully to ensure the result is within specific anodisation parameters.

Step 3: Incorporating the antimicrobial agents

The antimicrobial substances (active agents are quartenary ammoniums N-Alkyl Chloride and Didecyl Dimethyl Ammonium Chloride) are then bound to the nanostructured aluminium oxide surface pores formed during anodisation, up to a thickness of 50 microns.

Step 3: Finishing

The surface is then finished to ensure a smooth hard surface, ensuring it is easy to wipe down with soapy water if needed.

Want to find out more? Talk to us.